Experts in metalwork

Contact our staff

COMPANY HISTORY

The sotry of Loda Carpenteria Srl begins with a peasant family that set up business as blacksmiths in Ponoglio. In 1907, Carlo Loda took up residence inside a courtyard working with wrought iron which was heated in the forge, however, he also never neglected his fields.

In the mid-1900s, railing and gate production was replaced with agricultural products that his son, Giovanni, made.

At the beginning of the 1970s, Giovanni's son, Paolo, who is now the actual owner, joined the company and the first mechanical equipment was purchased, such as shears, bending machines and welding machines to develop and renew processes. The excellent results that we achieved in the mechanical processing industry helped us invest in electronic machinery and, Loda Carpenteria Srl was founded in 1992.

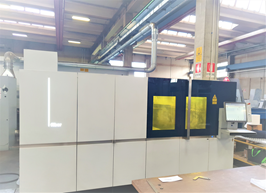

In 1994, the first laser technology machinery was purchased. This equipment allowed us to carry out extremely accurate and fast machining that had not been possible in the past. Laser cutting really was the true innovation of the sheet metal industry.

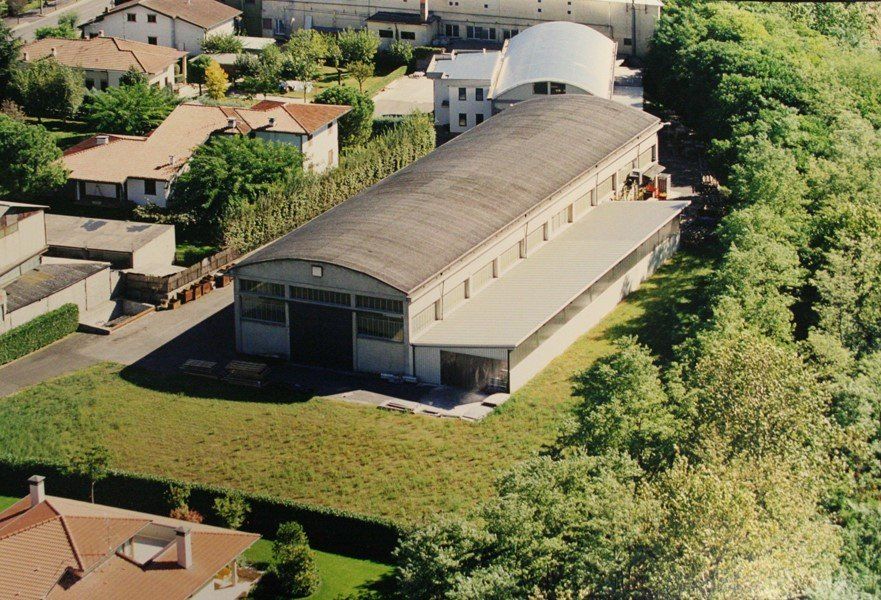

In 2007, our head offices were transferred to Pontoglio which renewed our company MO. The introduction of an additional laser cutting system, combined with an efficient production layout, has allowed us to expand the range of parts that we manufacture and also reduce production times.

In 2015, using fibre lasers further expanded our range of products.

Fibre technology now allows us to process other materials, such as brass and copper, as well as the 2000x4000mm working range which also allows us to process larger pieces.

In 2019, by expanding our plant and reorganising production layout, our company was then motivated to improve warehouse organisation, the internal logistical flow, and also how departments are divided up. Due to this reorganisation, a special welding department was then begun and set up to specifically help introduce robotic welding.

OUR COMPANY TODAY

From a long history that began in a farmhouse courtyard, Loda Carpenteria Srl now covers an area of about 6,000m, employs 40 people and generates a turnover of around 5 million.

Our main business is in processing sheet metal sheet mostly for third party clients. We can carry out a vast amount of processes using countless different metals. This allow us to work with well-known machinery and equipment manufacturing companies within the agricultural, forestry, food, textile, and nautical industries, as well as others specialised fields.

Over the years, Loda Carpenteria Srl has kept up to speed with new technology used in shaping sheet metal and we have invested in more competitive machinery. This innovative footprint distinguishes us from the rest. In future, we will continue to constantly update our equipment and machinery as well as introduce any new processes.

Our technical team play a fundamental role beginning with analysing our customer's project, making prototypes, developing drawings all the way through to production assistance when each piece is being made.

We use first rate raw material, purchased from qualified suppliers that have been issued the 3.1 certificate. The products are all able to be traced according to the regulations in the UNI EN ISO: 9001-2015 standard, and we keep them well stored.

Our production cycle begins with either laser cutting or punching the product into its finished shape. Then, by using special presses, products are calendered, or folded, and then assembled through different forms of welding which is finished off by grinding and polishing. The final stage of this entire process cycle is when the warehouse makes all necessary checks and decides if the pieces are manufactured well.

When required by clients, Loda Carpenteria Srl will take care of any surface treatments to be carried out, such as galvanizing, pickling and painting through carefully selected suppliers.

We pay particular attention to quality during each and every phase, and we are UNI EN ISO 9001: 2015 standard certified.

Fill out the form below for more information

If you would like more information, contact our metalworking experts with a quick phone call