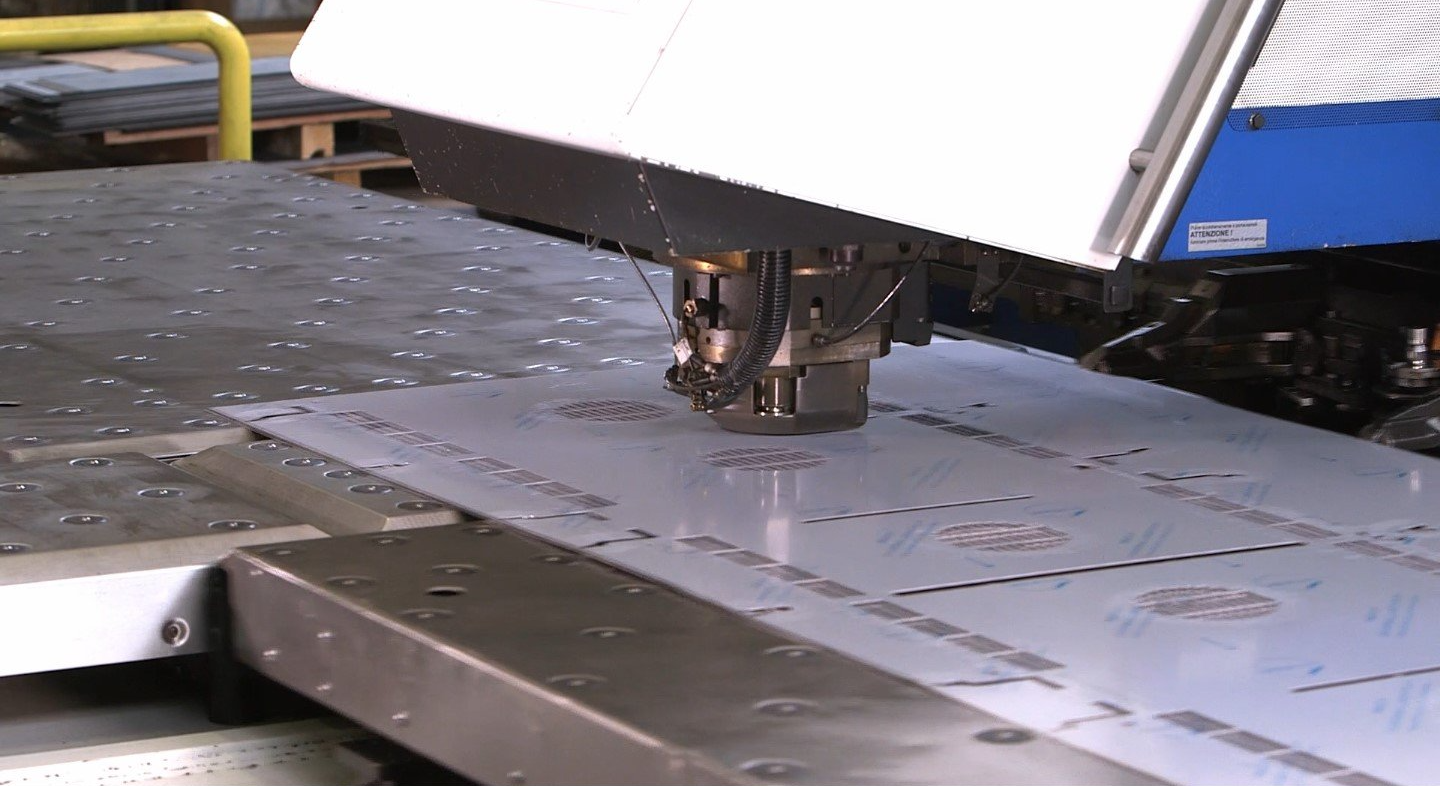

High precision metal cutting machinery

Get more info

Innovation and tradition are intertwined through our business at Loda Carpenteria. On one hand, we have always carefully looked at any new additions to the industry, using high-precision metal cutting machinery which is capable of giving impeccable results.

However, on the other hand, we still implement some activities, most of which are done by hand, as well as having some equipment that have roots in metal fabrication history, so that we can quickly respond and adapt to our customer's needs.

The processes that we carry out at Loda Carpenteria Srl work in transforming the outline or shape obtained from the sheet into a semi-finished or finished product.

Our main processes are: punching, bending, welding and finishing.

Additional processing, such as mechanical processing and surface treatments, are carried out on request by using external contractors.

High-precision and high-quality workmanship is helped along due to the location of our production departments and design warehouses so that logistic flow between departments is as high as possible in order to reduce processing times.

Delivery with full documentation

At Loda Carpenteria, we not have have high-precision cutting machines, but we also have an efficient monitoring and logistics system, which checks the quality of parts and packaging before preparing your deliveries, which is complete with the required documentation.

Book a delivery

Once your goods are ready, there are two options, you can either collect them directly from our head offices in Pontoglio, near Brescia, or we can organise them to be shipped throughout Italy to you as we have formed partnerships with reliable courier services.

Certified and traceable materials

The high-precision metal cutting machinery that we have available at Loda Carpenteria is not enough to guarantee high-quality of the final result, since it is essential to work on quality raw materials. For this reason, we choose and assess suppliers according to the UNI EN ISO 9001: 2008 standard criteria and purchase metal sheets of upto 1500x3000 mm in size that meet the UNI EN 10051: 2011 standard criteria. All materials used in our production process are traceable, insured against damage and theft, and include a 3.1 certificate issued by the manufacturing steel mill.

Special finishes

The standard materials stored in our warehouse are:

- UNI EN 10025-2: 2005 S235 pickled sheet

- UNI EN 10025-2: 2005 S275 pickled sheet

- UNI EN 10149-2: 1997 S355 pickled sheet

- UNI EN 10111: 2008 DD11 / DD12 / DD13 pickled sheet

- UNI EN 10088-2: 2005 X5CrNi18-10 (1.4301) stainless steel

We also use:

- 5754 H111 aluminium

- UNI EN 10130: 2007 DC01 sheet

- HARDOX / DOMEX sheet metal

- galvanized and electro-galvanized sheets

Fill out the form below for more information

Call our offices to find out more about the technical features of our high-precision cutting machinery